Mills in Altoaragón - aceitero 2

Mipanas

Mipanas,

situated on the shore of the

Embalse de El Grado, was the middle

of nowhere. The new connection from L'Ainsa to Barbastro brought Mipanas

nearer to the modern world. Park the car where Mipanas is signposted. There

is enough space next to the garbage containers. Walk the gravel road towards the

village. You'll soon pass the first mill and easily reach the village. Once there pass through the

arch at the right. At the end of the corridor is the mill (22).

Pictures: 3.i.2010

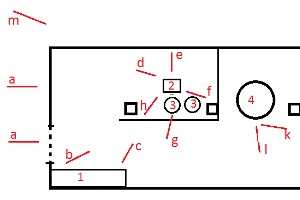

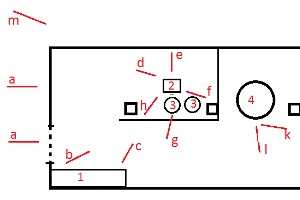

(21) Mipanas — mill is the low construction in the center (see also pict. 1, black circle).

(22) Molino - viewpoint m.

(23) front: entrance is at the right - vpt a.

The mill inside the village doesn't give its purpose away

from the outside. It's a two storey construction (22) which looks like a regular house —meaning

that the mill at hand is probably younger than the one outside. No provisions are made for a

huge cantilever press.

The bottom floor is the mill proper and the top floor looks like living quarters.

Apart form a small spy hole (visible in 28 top right) there is no communication between both floors.

The have a dedicated entrance each: at the center of the long side for the top (22) and

in the short side (23) for the work floor.

The short wall which formed the façade of the molino

collapsed and now blocks the door: not really a problem because the openings in the

wall are wide enough. It is already clear from the outside (23) that there are

two levels in the ceilings. The ceiling at the left is heightened to give the press

enough headroom. The floor at the right (23) above the door is much lower.

It is not safe to enter through the door, but the opening in the wall

at the left is a good alternative if you tread carefully. The press (25) is the first

thing you'll stumble upon and worth the effort on its own.

(24) interior - vpt b.

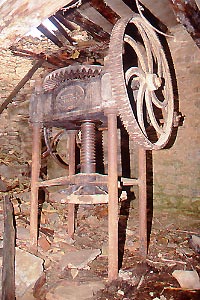

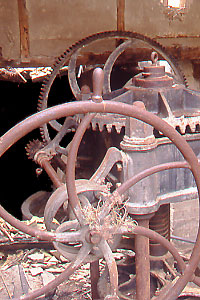

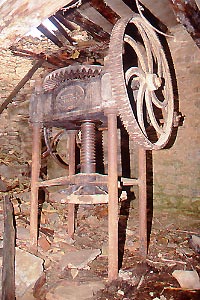

(25) screw press - vpt h.

(26) press - vpt f.

(27) press - vpt e.

(28) press - vpt d.

The press is mounted on an elevated part of the floor (24).

This required adjustment of the ceiling above that section (25,23). That could have been avoided

had the containers (30; 3 in drawing 37) which received the fresh oil been sunk into the floor. The bottom was

perhaps too rocky to be hollowed out.

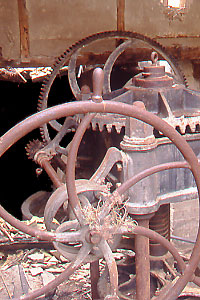

I have already explained that —apart from the small footprint—

the big advantage of this type of press was that one person could run it alone. This

was made possible because many turns of the wheel resulted in minute movements

of the plate of the press. The reduction ratio is about 7 to 1 in the first step (28) and I presume

that gears hidden in the head provide a much higher ratio.

Fundicion y Construccion D Maquinas

M Rodon H°

Zaragoza

J M Rodriguez Lacomme Ingeniero

(29) label on the press.

The label of the press is most interesting (29).

It is the first time we have found a press made by the Rodón company.

Rodón —based in Zaragoza— was a contemporary of Averly and

La Maquinista Aragonesa. The company was founded by the brothers Sebastián

and Martín Rodón Serra (1862).

I have found a Rodriguez Lacomme, Jose Ma. in the lists

of industrial engineers graduated in 1876 at the Escola Técnica Superior

d'Enginyeria Industrial de Barcelona. This probably gives us an earliest date of this specimen.

(30) foot of press with oil containers - vpt g.

(31) mats for the press.

(32) balsa - vpt k.

(33) balsa - vpt l.

Deep in the room, at the far end from the door, is the crushing contraption

situated (4 in the drawing 37). It is an elevated flat surrounded by a small gutter which widens into a box where

the olive paste could be collected (32, 33).

An edge stone and a funnel (tolva

) are mounted on a vertical axle (34).

Olives where poured into the funnel. The small door with lever (35) regulated the flow towards the

zone where they were crushed under the weight of the stone.

(34) balsa with tolva and ruello.

(35) tolva with valve.

Several rods (mounted on the tolva, 34) kept the olives

in the path of the stone. A small vane in the gutter pushed the paste to the collecting box.

The system is rather sophisticated and we have seen a similar tool

in

Troncedo. In many other mills the contraption used to

crush the olives is much more primitive (e.g.

Sieste,

Trillo).

(36) storage - vpt c.

(37) Floorplan with camera viewpoints (vpt).