El Grado

Pictures: 03.i.2012

Pictures: 03.i.2012

| oil mill | flour mill |

el torno, right in 2 & 3). In most mills of the wide region the olives were crushed under a huge dishlike stone (the

ruello) running on its side (e.g. Buera, Coscojuela de Sobrarbe). Here, however, crushing was done with a pair of conic stones. This type of stones has a larger working surface and causes less friction on the olives.

batidora, for malaxation.

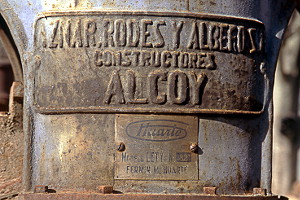

The mixer was delivered by from Alcoy (prov. of Alicante)(7).

Tomás Aznar y hermanosestablished much earlier in 1830. Part of the Tomás business would in 1896 relocate to Alicante and work under the name

Tomás Aznar e hijos(sons instead of brothers). The second name is of who owned the oldest foundry (est. 1886) in Alicante. , or in full Francisco Albero Rodes, was a former manager of the foundry.

Lety means that this is more than a simple batidora (mixer, which can be seen in Buera); it is a batidora-extractora (mixer, extractor) which not only homogenizes the olive mash but also extracts 50, up to 80, percent of the oil (†). The contraption contains two chambers separated by a metal mesh. The first chamber is a heater-mixer. This mixer is surrounded by a cylinder in which the mash slowly moves upwards. This type of extractor could process up to 1 000 kilos of mash per hour and would in some situations make the use of the press superfluous.

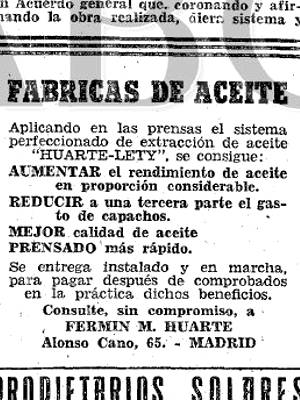

An advertisement of 1953 (6) neatly enumerates all the advantages of the system. Another advert (ABC of 29.iii.1962) concludes in one sentence: Mas y mejor aceite y elaboración mas facil y regular, y mucho menos costosa.

(more and better oil, easier and cheaper

processing). In fact the supplier has such confidence in the advantages of his Lety process that he only expects payment after the device is in operation and the new owner convinced of the benefits (6).

The name of the company is and presses of the same company were in use in f.e. Banastón and Alquézar.

vagonetas) (see Angüés). The rail system was built as a star with a turntable in the center (the circle in 9) and with arms radiating to the press, the mixer and the grinder.

When we went back in 2016, the site was cleared of the vegetation and the grinder was removed (9). We were told that the site was for sale and intended for buildings.

| oil mill | flour mill |

† — 1947 — Extracción de aceite por el método Acapulco.

Agricultura Año XVI, N°180, p. 199-200.